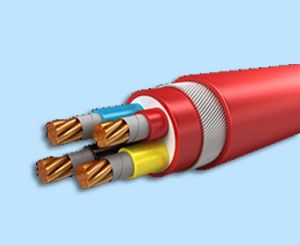

Fire Survival Cable

VISION offers Fire Survival Cables With a High Level Of Safety for Fire – Prone Areas, They are used in hazardous situationswhere the human life and precious materials are at risk of fire, Such as all power plants (Nuclear, Thermal,Gas,Crude and Solar etc.), Railways stations, airports, shopping complexes,movie halls and so on. They are also known as CIRCUIT SAFETY CABLES, and are made to withstand high temperatures for a set amount of time under direct fire and can resist temperatures up to 650 ⁰C,750 ⁰C and 950 ⁰C under diverse operating situations and applications, because of their properties that prevent them from overheating

Dimensions

Circular Conductor

- Sizes up to and including 16mm² are offered

Shapped Conductor

- 25 mm² and onward

Construction

- Plain annealed stranded copper conductors.

Insulation

- Mica (fire - resistant) Tape.Covered by an extruded layer of cross-linked polyrthylene.

Bending

- A layer of extruded thermoplastic low smoke zero halogen(LSZH) compound

Sheath

- Thermoplastic low smoke zero halogen(LSZH) compound

Armour

- Glavanised Steel wire.

Technical Data

Voltage Rating

- 600/1000V

Minimum Bending Radius

- 12 X

Operating Temperature

- 40⁰C to 90⁰C

FIRE SURVIVAL CABLE

Fire Survival Cable - Technical Datasheet

| S.no | Description | UOM | |

|---|---|---|---|

| 1 | Volatage Grade | Volts | 600/1000 |

| 2 | No of Cores | - | 2 |

| 3 | Conductor | ||

| a | Material | Electrolytlc Grade Stranded & Circular Annealed Bare Copper Conductor conf to BS : 6360 | |

| b | Size | Sqmm | 1.50 |

| b | No. of strands | NO1 | 7 |

| 4 | Wrapping Over Conductor | ||

| a | Material | Double layer of Glass Mica Tape | |

| b | Thickness (Nom) | mm | 0.135 |

| c | Coverage/Overlap | 100/30 | |

| 5 | Insulation | ||

| 5 | Insulation | ||

| a | Material | Extruded XLPE GP-8 conf. to BS EN7655-1.3 | |

| b | Thickness (Nom) | mm | 0.60 |

| c | Core Identification | Blue & Brown | |

| 6 | Screening (Overall) | ||

| a | Material | Aluminium- Iyler Tape | |

| b | Type | Helical | |

| c | Thickness (Min) | mm | 0.050 |

| d | Overlap | 25 | |

| e | Coverage | 100 | |

| 7 | Drain wire (Overall Screening) | ||

| a | Material | Annealed Tinned Copper Conductor | |

| b | Size | Sqmm | 0.5 |

| c | No.of strand | Nos | 7 |

| 8 | Bedding | ||

| a | Material | Extruded LSZH LTS-1 conf. to BS Ei4 : 7655-6.1 | |

| b | Thickness [Nom) | mm | 0.80 |

| c | Colour of inner Sheath | Black | |

| 9 | Rip Cord | Hon metallic rip cord has been provlded below inner sheath | |

| 10 | Armour | - | - |

| a | Material | - | Galvanised Steel Round wire conf to BS EN : 7846 |

| b | Type | - | Single Layer |

| c | Size (Nom) | mm | 0.9 |

| 11 | Outer Sheath | - | - |

| a | Material | - | Extruded LSZH LTS- 1 conf. to BS EN : 76SS-6.1 |

| b | Thickness (Nom) | - | 1.30 |

| c | Colour of Outer Sheath | - | - |

| d | Approx Overall Diameter of cable | mm | 13.1 |

| e | Tolerance on Overall Diameter of cable | mm | ±2 |

Fire Survival Cable - Technical Datasheet

| S.no | Description | UOM | |

|---|---|---|---|

| 12 | Electrical Parameters | - | - |

| a | Max.D.C. Resistance of Conductor at 20°C of complete cable | ohm/km | 12.1 |

| b | Min. Insulation Resistance of conductor at 20°C of complete cable | Mohm/km | 1000 |

| c | Max. Mutual Capacitance at 0.8 kHz (core to core) | yr/mtrs | 150 |

| d | Max. Mutual Capacitance at 0.8 kHz (core to screen) | /mtr | 400 |

| e | L/R Ratio (Max) | - | 40 |

| f | Max. Drain wire Resistance including shielding at 20°C of complete cable | ohm/m | 30 |

| g | High Voltage Test(core to core & core to screen) | kv rms | 1 kV fo r 1 Minute |

| 12 | LSZH Properties on Bedding & Outer sheath | - | - |

| a | Min.Oxygen index as per ASTM D-2863 | % | 30 |

| b | Min.Temperature index as per ASTM D- 2B63 | °C | 275 |

| c | Max.HCL emission as per IEC60754 -1 | % | 0.5 |

| d | Max.smoke density rating as per ASTM D- 2843 | % | 20 |

| e | Min.Light Transmission as per IEC-6 1034- 1 &2 | % | 70 |

| 13 | Flammability test on completed cable | Cable shall meet test requirement as per lEC-60332-1 -2 & SS-424- 147S Clause F3 | |

| 14 | Circuit Integrity Test as per BS EN7846 & B5 EN 6387 | - | Category F1 (Fire Alone Test) : The Cable Shall withstand at a temp of 950 °C for 3 Hours accordance to BS EN 6387 |

| - | Category F2 (Resistance to fire & Resistance Fire with water):The Cable Shall withstand at a temp of 950 °C for 3 Hours accordance toBS EN 6387 | ||

| - | Category F3 (Resistance to fire with mechanical shocks & water) The Cable Shall withstand at a temp of 95O °C for 3 Hours to BS EN 6387 | ||

| 15 | Circuit Integrity Test as per IEC60331-21/23(Fire Alone Test) | - | Shall withstant at a temp of 750 °C for 3 Hours |

| 16 | Marking on outer sheath | - | OCEAN ,TYPE OF CABLE ,SIZE,N0 0F CORES,VOLTAGE GRADE,YEAR OF MANUFACTURING |

| 17 | Drum Length | mtrs | 500 / 1000 |

| 18 | Quantity Tolerance | % | +5 |

Fire Alarm Cable, Fire Resistant low smoke zero halogen, overall screened, Red overall Sheath, 2 pair

| II.No | Description | DATA |

|---|---|---|

| 1 | No of Cores | 2 CORE |

| 2 | Size in Sq.mm. | 1.5 |

| 3 | Quantity Required | 5000 meters |

| 4 | Voltage Grade | 1100 V |

| 5 | Max.rated conductor temp in Deg.C | 70 |

| 6 | Conductor Material Properties | |

| (i) Material | EIectroIy1ic Grade Copper Slranded Class2 to IS 8130 / 1984 | |

| (ii) Shape | Circular | |

| (iii) Cross Sectional area (sq.mm) | 1.5 | |

| (iv) No. of wires | 7 | |

| 7 | Insulation Material Properties | |

| (i) Material | The extruded PVC COMPOUND TYPE A As Per IS 5831 | |

| (ii) Nominal Thickness in (mm) | 0.8 mm | |

| (iii) Core Color | Red. Black | |

| 8 | Overall Screening | Aluminium backed by mylar tape of nominal thickness of 0.075 mm with 25% Overlap and 100% coverage shall be applied over cores. ATC Drain wire of 0.5 sq mm multi strand tinned annealed copper conductor shall be provided under Aluminium Mylar tape in continuous contact with AI. |

| 9 | Rip cord | Non metallic rip cord shall be provided below inner sheath |

| 10 | Approx. Overall Dia of Cable (mm) (tolerance +/- 2mm) | 12 |

| 11 | Std. length of cable per drum (tolerance +/- 5%) (m) | 1000 |

| 12 | Minimum bending radius | 12 times of Overall Diameler |

| 13 | Marking/printing on outer sheath | 1100V. FIRE ALARM CABLE. 2-CORE x 1.5SOMM. FR-LSH. YEAR. METERING |

Fire Alarm Cable, Fire Resistant low smoke zero halogen, overall screened, Red overall Sheath, 2 pair

| II.No | Description | DATA |

|---|---|---|

| 14 | Inner Sheath Material Properties | |

| (i) Material | PVC COMPOUND TYPE ST1 As Per IS 5831 | |

| (ii) Extruded or Wrapped | Extruded | |

| (iii) Minimum Thickness (mm) | 0.3 | |

| (iv) Color | Black | |

| 15 | ARMOUR Properties | |

| (i) Material | SINGLE GS ROUND WIRE As Per IS 3975 | |

| (ii) Type of Armour | ROUND WIRE | |

| (iii) Nominal Dimensions (mm) | 1.4 | |

| 16 | Outer Sheath Material Properties | |

| (i) Material | Extruded FR-LSH PVC Compound Type ST1 As Per IS 5831 | |

| (ii) Min. thickness (mm) | 1.24 | |

| (iii) Colour | Fire Red Colour | |

| 17 | Electrical Parameters | |

| (i) Max. DC Resistance of conductor at 20°C (ohm/km) | ≤ 12.1 | |

| (ii) Max. DC Resistance of Drain+Shield (ohm/km) | ≤ 30 | |

| (iii) H.V. Test ( core & Screen ) | 1 KV for 1 min | |

| (iv) lnsuIation Resistance(Megger test) | z 25 M-ohm | |

| 18 | FRLSH Properties | |

| (i) Oxygen Index at room lemperature as per ASTMD-2863 | Min.29% | |

| (ii) Temperature Index As per ASTMD2863 | Min. 250 Deg C at 21% Oxygen index | |

| (iii) Smoke density Rating as per ATSMD2843 | Smoke density rating maximum 60% and Light transmittance 40% minimum | |

| (iv) Max. HCL Emission as per IEC 60754-1 | 20% Max. (by Weight) | |

| (iv) Flammability Test | As per IEC-60332-1/SS-424-1475/ IEEE383/IEC-60332-3 |

Note : The Conductor Size shall be According to the Resistance Value & it's Tolerance specified in IS:8130-1984

APPROVALS